In the maritime sector, maintaining the integrity of piping systems is essential. Leaks, fractures, and corrosion can result in considerable operational interruptions and expensive repairs. This is where a Pipe Repair Kit proves to be indispensable. With products such as FASEAL Water Activated Tapes, ship operators can perform swift repairs both efficiently and effectively. This article will walk you through the procedure of utilizing a pipe repair kit, highlighting safety measures and best operational practices.

Understanding the Pipe Repair Kit

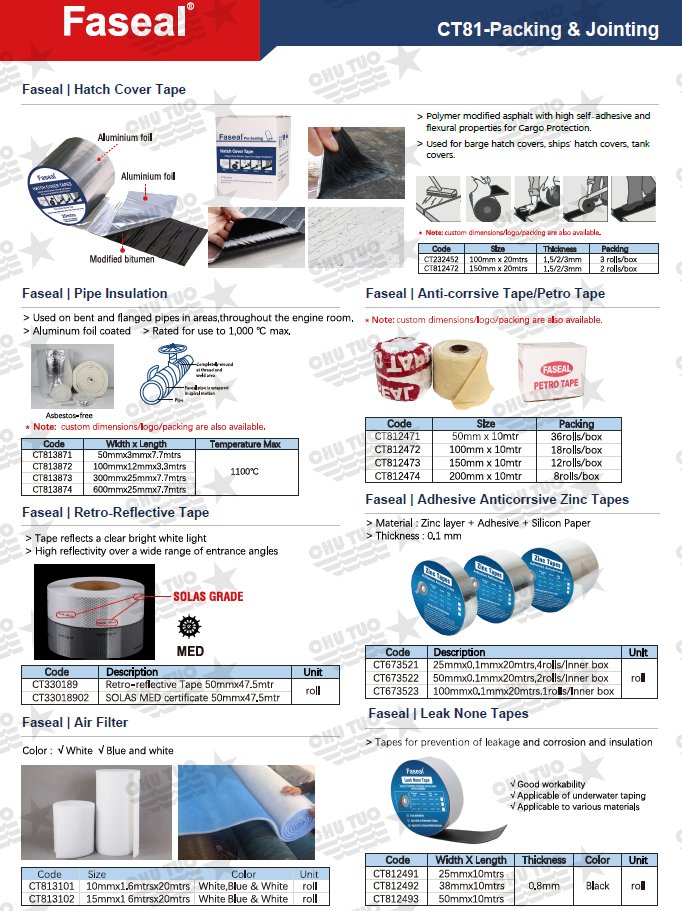

FASEAL Water Activated Tape: This cutting-edge tape is made from a water-activated material that changes from a flexible adhesive to a solid seal upon application. It comes in various dimensions, including 50mm x 1.5m, 75mm x 2.7m, and 100mm x 3.6m. This tape enhances repairs, offering high durability and pressure resistance, making it appropriate for a range of piping materials.

Step-by-Step Instructions for Utilizing a Pipe Repair Kit

Step 1: Evaluate the Damage

Prior to initiating any repairs, conduct a thorough inspection of the pipe to determine the severity of the damage. Assess whether the leak is minor or if it necessitates more comprehensive actions. Shut off the water or fluid supply to avert further leaks during the repair procedure.

Step 2: Prepare the Surrounding Area

Clean the area surrounding the leak. Eliminate any dirt, grease, or corrosion to guarantee that the tape adheres effectively. A clean and dry surface is vital for achieving a successful seal.

Step 3: Activate the Tape

Wear protective gloves and open water bag. Fill bag with water. Press several times to allow water to flow out of the bag. Squeeze out excess water and start wrapping.

Step 4: Apply the Tape

Wrap the activated tape around the damaged section of the pipe. Here are some crucial tips for application:

Correct Wrapping Technique: Ensure that the tape overlaps by at least 50% with each layer to form a robust seal.

Timing: The curing duration will differ based on the ambient temperature. At 2℃ (36℉), allow 15 minutes; at 25℃ (77℉), allow 8 minutes; and at 50℃ (122℉), allow 4 minutes for curing.

Step 5: Test the Repair

Once the curing period has elapsed, restore the water supply and inspect for leaks. If the repair is successful, you can be assured of the pipe’s integrity.

Temperature Considerations:

If the ambient temperature is below freezing, warm the pipe and tape to above 2℃ (35℉) for optimal bonding. Conversely, if it exceeds 40℃ (104℉), refrain from adding water during the application.

Safety Precautions

Using a pipe repair kit requires handling materials that may cause irritation. Below are crucial safety measures:

Eye Protection: Prevent eye contact; if contact occurs, rinse immediately with water for 10 minutes and seek medical assistance.

Skin Contact: In case the uncured material touches the skin, remove it with a clean towel and wash thoroughly using alcohol and acetone. Seek medical help if swelling or redness develops. Cured material will naturally come off over a few days.

Ventilation: Always operate in well-ventilated spaces to reduce the inhalation of any fumes.

Storage and Shelf Life

Proper storage enhances the longevity of your pipe repair kit:

Ideal Conditions: Keep it in a dry, cool environment below 40℃ (104℉), ideally under 30℃ (86℉). Avoid exposure to direct sunlight, rain, or snow.

Best Before Date: The tape has a shelf life of two years from the manufacturing date, so regularly check expiration dates.

Why Choose ChutuoMarine for Your Pipe Repair Needs?

ChutuoMarine is recognized as a reliable supplier in the maritime sector, providing high-quality repair solutions. As an IMPA-approved ship wholesaler and ship chandler, ChutuoMarine offers dependable products that fulfill the requirements of marine operations. Their Pipe Repair Kits are crafted for durability and user-friendliness, making them perfect for quick repairs on vessels.

Click to view the making video: Water Activated Tapes Pipe Repair Tape

Conclusion

Effectively utilizing a Pipe Repair Kit is vital for preserving the integrity of marine piping systems. With FASEAL Water Activated Tapes, swift repairs can be performed seamlessly. By adhering to the specified steps and following safety precautions, ship operators can guarantee the durability and reliability of their piping systems. For further information or to acquire a pipe repair kit, please reach out to ChutuoMarine at marketing@chutuomarine.com, your trusted partner in marine supply solutions.

Post time: Jul-21-2025