In the challenging realm of maritime operations, the necessity for dependable and efficient equipment cannot be overstated. The Marine QBK Pump, part of ChutuoMarine’s pneumatic diaphragm pump series, is designed to manage a diverse range of fluids, rendering it an invaluable resource for ship chandlers and suppliers. This article will discuss strategies to enhance the efficiency of your QBK pump, guaranteeing peak performance and durability while emphasizing its essential characteristics.

Understanding the QBK Pump

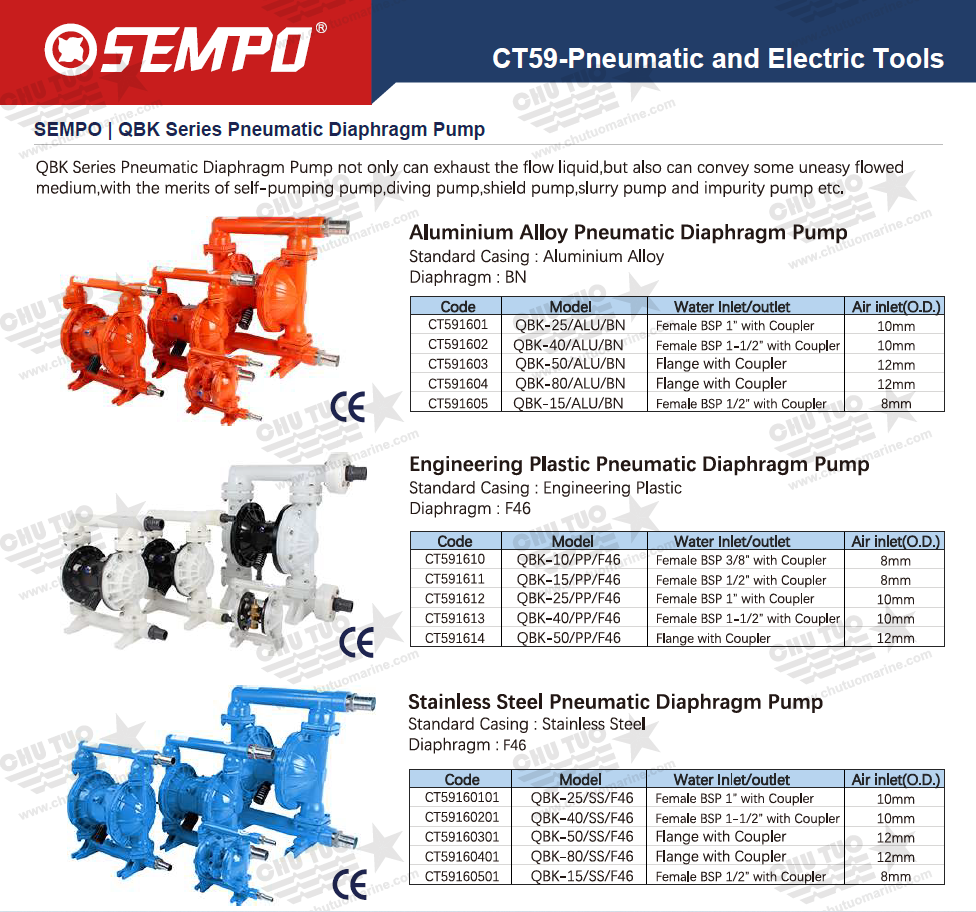

The QBK series air-operated aluminum diaphragm pump is engineered for diverse applications, including sewage management on vessels, diesel oil transfer, and the handling of aggressive chemicals. Constructed from aluminum alloy, it offers durability and corrosion resistance, making it ideal for challenging marine conditions. Furthermore, the pump’s CE certification confirms adherence to safety and quality standards, ensuring dependable performance in essential operations.

Essential Characteristics of the QBK Pump:

1. No Electricity Required: The QBK pump functions without electricity, utilizing compressed air, which ensures safety in flammable or explosive settings. This aspect is especially vital in maritime contexts where electrical risks are prevalent.

2. High Suction Lift: It boasts a suction lift capacity of up to 5 meters and a delivery lift of 50 meters, enabling effective management of various fluids without requiring extra equipment.

3. Wide Flow Capacity: The pump accommodates a diameter of up to 10mm, facilitating the movement of slurry and impurities with minimal wear.

4. Simple Operation: Its design is uncomplicated, featuring no rotating components, which simplifies operation and maintenance, thereby decreasing the likelihood of mechanical failures, a critical factor in marine environments.

5. Self-Protection Function: Additionally, the pump includes a self-protection mechanism that halts operation during overload situations to avert potential damage.

Enhancing Efficiency: Recommended Practices

To achieve optimal performance from your QBK pump, it is essential to implement the following recommended practices:

1. Routine Maintenance

Routine maintenance plays a vital role in enhancing the efficiency of your QBK pump. Consider these maintenance suggestions:

Inspect Seals and Diaphragms: Regularly examine the diaphragm and seals for signs of wear. Replace them as needed to avoid leaks and ensure peak performance.

Clean the Pump: After each use, clean the pump thoroughly to eliminate any residues that may hinder its operation, particularly when dealing with corrosive or viscous substances.

Air Filter Maintenance: Verify that the air filter is clean and functioning effectively. A blocked filter can diminish efficiency and cause performance complications.

2. Correct Installation

Proper installation is essential for the pump’s effectiveness:

Adhere to Manufacturer Guidelines: Always follow the installation instructions provided by ChutuoMarine. Correct installation guarantees that the pump functions as designed and reduces the likelihood of damage.

Utilize Suitable Hoses and Connections: Ensure that hoses and connections are appropriate for the fluids being processed and are securely fastened to prevent leaks.

3. Optimize Operating

Conditions Enhancing the efficiency of your QBK pump also requires optimizing its operating conditions:

Temperature Control: The pump performs optimally within a temperature range of 5 to 65 degrees Celsius. Ensure that the surrounding conditions remain within this range to avoid operational difficulties.

Monitor Liquid Viscosity: The QBK pump is capable of handling liquids with viscosities up to 10,000 cps. Ensure that the fluids being pumped do not exceed this viscosity to sustain efficient operation.

4. Ensure Proper Pneumatic Pressure

The efficiency of the QBK pump is greatly influenced by the pneumatic pressure applied:

Adjust Pressure Settings: The QBK pump permits pressure modifications ranging from 1-7 bar. Tailor the pressure settings to the specific application to improve flow rates and overall efficiency.

Employ Variable Speed Control: If available, utilize variable speed control to align the pump speed with the characteristics of the fluid and the requirements of the application.

5. Educate Your Team

Ensuring that your team is thoroughly trained in the operation and maintenance of the QBK pump can greatly improve its efficiency:

Offer Extensive Training: Instruct your team on the pump’s features, correct operation, and maintenance protocols. A knowledgeable team is crucial for avoiding operational mistakes and optimizing pump performance.

Develop Standard Operating Procedures (SOPs): Formulate and implement SOPs for the operation and maintenance of the QBK pump to guarantee consistency and efficiency in its use.

Conclusion

Enhancing the efficiency of your Marine QBK Pump is vital for ensuring seamless operations in maritime settings. By adhering to best practices in maintenance, installation, and operation, you can significantly improve the performance and lifespan of this essential pneumatic equipment.

As a ship chandler or wholesale supplier, investing in high-quality equipment like the QBK series from ChutuoMarine not only enhances operational efficiency but also ensures adherence to industry standards such as IMPA. With its durable construction and dependable performance, the QBK pump is recognized as a preferred option for managing various fluids in marine applications.

For those aiming to improve their maritime operations, consider the benefits of the QBK pump. Collaborate with ChutuoMarine to access premium pneumatic diaphragm pumps that fulfill your requirements for efficiency and reliability. Reach out to us today to discover more about our products and how they can enhance your operations.

Post time: Apr-30-2025