Marine anti-splashing tape is an important tool for enhancing safety and protecting your boat’s surfaces. However, simply having the tape isn’t enough; using it correctly is essential to maximizing its effectiveness. In this article, we’ll walk you through the steps to effectively use marine anti-splashing tape, ensuring a safe and long-lasting installation.

Gather Materials

Before you begin, make sure you have all the necessary materials:

1. Marine anti-splashing tape: Choose the appropriate width and length for where you plan to use it.

2. Surface Cleaner: Use an appropriate cleaning solution, such as isopropyl alcohol, to prepare the surface.

3. Cloth or paper towels: For cleaning and drying the surface.

4. Tape measure: Measure the length of tape you need.

5. Utility knife or scissors: For cutting the tape to the desired length.

6. Rubber scraper or roller: For smoothing the tape after application.

PreparationClean the area:

First, thoroughly clean the surface you plan to apply the tape to. Remove any dirt, grease, or moisture to ensure a secure bond. Use a cloth soaked in your chosen cleaner to wipe the area until it is clean.

1. Dry Surface:

Allow the surface to dry completely before proceeding. Moisture can affect the adhesive quality of the tape, leading to poor adhesion and premature failure.

2. Measure Length:

Use a tape measure to determine how much tape you need. Any curves or angles of the surface must be accounted for for an accurate fit.

3. Cut Tape:

Use a utility knife or scissors to cut the tape to the measured length. Make sure you cut it straight to get a clean edge, which will help it seal better when applied.

Flange Installation of Marine Splash Tape

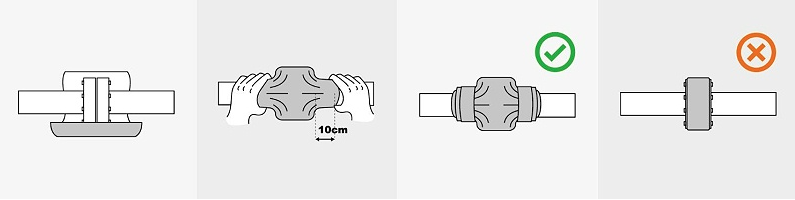

1. Cover the entire flange with the cut anti-splashing tape. The width of the splash tape should be enough to cover the entire flange and about 50-100mm of pipe on both sides of the flange (depending on the flange diameter), and the length should allow it to wrap around the entire diameter of the flange with a 20% overlap (but not less than 80mm).

2. Press the anti-splashing tape firmly on both sides of the flange as shown to minimize the gap under the tape.

3. Wrap two more anti-splashing tape on each side of the flange, with a width between 35-50mm (depending on the flange diameter). The length should be enough to wrap around both sides of the installed tape, overlapping at least 20%.

If installed on a valve or other irregularly shaped object, the entire surface must be covered with the anti-splashing tape (except for the adjustment lever or knob).

Valve Installation of Marine Splash Tape

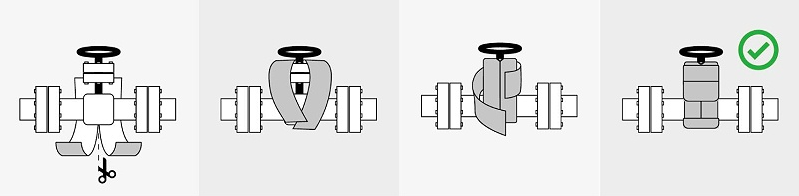

1. Prepare a square anti-splashing tape large enough to wrap around the valve from both sides. It may be useful to make a partial cut along the center of the prepared splash tape so that it can be installed on both sides of the adjustment knob, as shown in the figure below.

2. Wrap the valve in a vertical direction.

3. Use additional splash tape to wrap the valve in a horizontal direction.

4. A properly installed tape should completely cover the protected element.

Final Inspection

1. Check for bubbles: After applying, check the tape for bubbles or gaps. If any bubbles or gaps are found, use a rubber scraper to push the air to the edges.

2. Secure the edges: Make sure the edges of the tape are fully adhered to the surface. If necessary, apply additional pressure to these areas to enhance adhesion.

3. Let the tape sit for at least 24 hours before exposing it to water or frequent use. This waiting period allows the adhesive to bond securely to the surface, ensuring optimal performance.

Additional Notes

1. The splash tape must not have any visible surface damage. If any damage is found, it should be replaced with new material.

2. The tape can be cut with scissors or a sharp knife. During installation, the release liner should be peeled off gradually to avoid soiling the adhesive layer, which can lead to a loss of adhesive performance.

3. Use pliers or a sharp knife to separate the tape. Peeled tape cannot be reused.

4. Do not wrap too tightly. The tape should be loose enough to allow the oil to flow freely.

Maintenance and Storage

The material should be stored in a dry and cool place. It is recommended to store the rolls in the original packaging.

Conclusion

The effective use of marine splash tape requires careful preparation, accurate measurements, and thorough application. By following these steps, you can ensure that the tape performs well and provides the safety and protection your vessel needs. With proper installation, marine splash tape can help maintain a safe and clean environment on board, making it a worthwhile investment for any marine operation.

Post time: Nov-28-2024