In the maritime sector, the necessity for efficient and dependable equipment is paramount for a range of operations, including cargo handling and maintenance activities. Among the essential tools that have emerged in marine applications is the Marine Pneumatic Driven Winch. This article delves into the definition of a pneumatic driven winch, its operational mechanics, and its importance in marine operations, particularly for ship chandlers and those engaged in ship supply.

Click this link to watch the Marine Pneumatic Driven Winch display video: Pneumatic Driven Winches: product test display

Overview of Marine Pneumatic Driven Winches

Definition and Function

A Marine Pneumatic Driven Winch is a winch that utilizes compressed air as its power source, specifically engineered for lifting and pulling heavy loads in marine settings. In contrast to electric or hydraulic winches, pneumatic winches function through air pressure, offering distinct advantages in environments where electrical equipment may present safety hazards, such as in explosive or humid conditions.

These winches are particularly beneficial for activities such as tank cleaning, mooring, and general cargo handling, rendering them essential for ship chandlers and other maritime professionals.

Notable Characteristics

Marine pneumatic driven winches are equipped with several features that enhance their performance and safety:

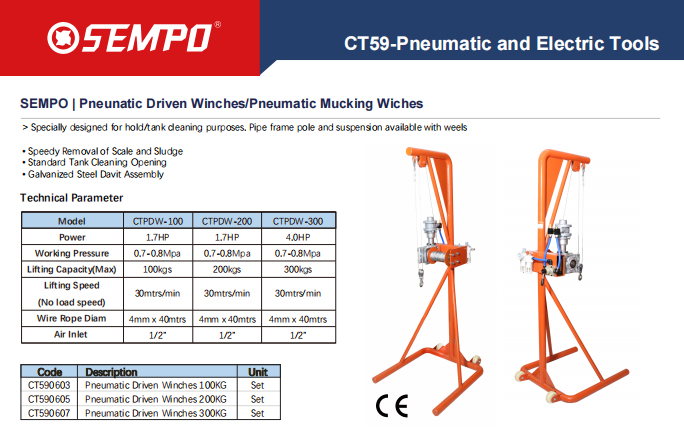

High Lifting Capacity: Models such as the CTPDW-100, CTPDW-200, and CTPDW-300 provide lifting capacities between 100 kg and 300 kg, making them versatile for various marine applications.

Operational Pressure: These winches generally function at a working pressure of 0.7-0.8 Mpa, allowing them to manage significant workloads effectively.

Lifting Speed: With a no-load lifting speed reaching up to 30 meters per minute, pneumatic winches enable rapid operations, which is vital for time-sensitive maritime tasks.

Robustness: Made from galvanized steel, these winches are built to endure the challenging conditions often encountered in marine environments, including exposure to saltwater.

Safety Features: Pneumatic winches are designed with safety mechanisms, such as dynamic and mechanical braking systems, which provide immediate stopping capabilities to avert accidents.

How Does a Marine Pneumatic Driven Winch Operate?

Operating Principles

The functionality of a marine pneumatic driven winch is based on the principles of compressed air. Below is an overview of the operational process of these winches:

Compressed Air Supply: A source of compressed air is essential for the winch, typically supplied by an air compressor. This device produces high-pressure air that is channeled into the winch.

Air Inlet: The winch features an air inlet, generally measuring 1/2 inch in diameter, through which the compressed air is introduced. This inlet regulates the airflow into the winch system.

Pneumatic Motor: Within the winch, the compressed air is directed to a pneumatic motor. This motor transforms the air pressure into mechanical energy, which powers the winch drum.

Drum and Wire Rope: The winch drum is equipped with a wire rope that can be either wound or unwound as the drum rotates. The action of the pneumatic motor causes the drum to turn, facilitating the lifting or lowering of the load attached to the rope.

Braking Systems: Upon completion of the lift, the winch employs its mechanical and dynamic braking systems to secure the load. This is vital for ensuring safety during operations.

Applications in Marine Operations

Marine pneumatic driven winches serve a variety of functions, including:

Tank Cleaning: These winches are specifically engineered for tasks such as removing sludge and scale from tanks, making them crucial for maintaining cleanliness and safety on board vessels.

Mooring Operations: Pneumatic winches play a key role in mooring ships by managing the lines used to secure vessels at docks or during anchoring.

Cargo Handling: Whether lifting heavy machinery or transporting supplies, pneumatic winches deliver the necessary strength and speed for effective cargo operations.

Maintenance Tasks: From lifting tools to conducting repairs, these winches are essential for ensuring that maintenance activities are performed efficiently and safely.

Advantages of Marine Pneumatic Driven Winches

Safety: The utilization of compressed air minimizes the likelihood of electrical hazards, rendering pneumatic winches safer for operation in wet or potentially explosive settings.

Efficiency: Featuring high lifting speeds and capacities, pneumatic winches can greatly enhance the efficiency of marine operations, facilitating quicker turnaround times.

Versatility: These winches are applicable in a wide range of scenarios, making them a multifunctional resource for ship chandlers and marine service providers.

Durability: Designed to endure harsh marine environments, pneumatic winches are less prone to wear and tear, leading to reduced maintenance expenses over time.

Ease of Use: With simple controls and mechanisms, pneumatic winches are user-friendly, enabling operators to concentrate on their tasks without the need for complex setups.

Conclusion

In the ever-evolving realm of maritime operations, Marine Pneumatic Driven Winches emerge as reliable, efficient, and safe solutions for lifting and pulling heavy loads. Their dependence on compressed air makes them particularly advantageous in environments where electrical equipment may present hazards, while their high lifting capacities and speeds contribute to enhanced operational efficiency.

For ship chandlers and marine service providers, the investment in pneumatic winches can result in increased productivity and safety across various tasks, ranging from tank cleaning to cargo handling. Gaining an understanding of the functionality and benefits of these winches is crucial for making informed choices in equipment selection, ensuring that maritime operations proceed smoothly and effectively.

Post time: Mar-12-2025