In the maritime sector, safeguarding cargo from water damage is of utmost importance. A vital tool for accomplishing this is the Hatch Cover Tape. This guide will explore the materials, uses, and advantages of hatch cover tapes, with a particular emphasis on Dry Cargo Hatch Sealing Tape and its importance in marine operations.

What is Hatch Cover Tape?

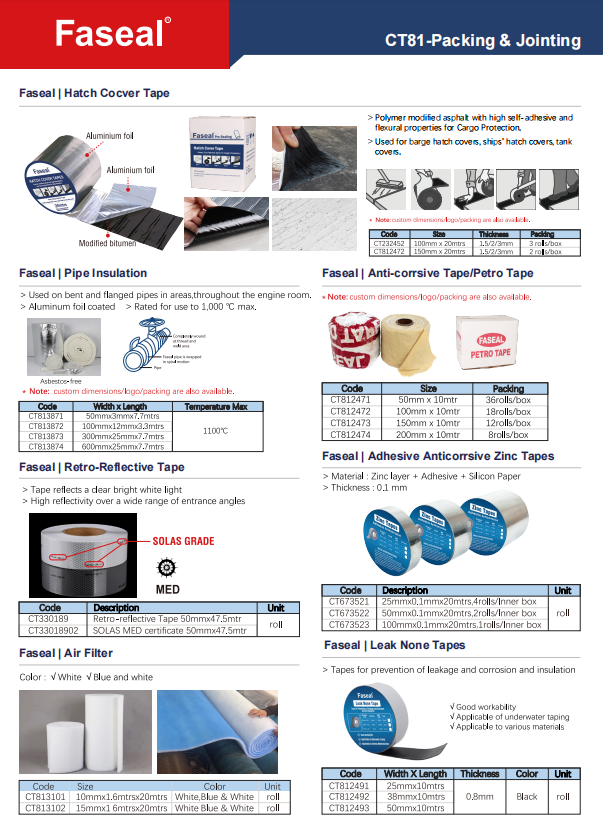

Hatch cover tape is a self-adhesive sealing tape specifically designed to establish a waterproof barrier on cargo hatch covers. It aids in preventing leakage during transportation, particularly in severe weather conditions. This tape is widely utilized in the shipping industry, where preserving the integrity of cargo is critical.

Materials Used in Hatch Cover Tapes

1. Bituminous Compound

The main material utilized in hatch cover tapes is a bituminous compound. This substance is recognized for its outstanding adhesive qualities and resilience. It offers a robust seal capable of enduring fluctuating temperatures and harsh environmental conditions.

2. Polypropylene Foil

Hatch cover tapes frequently incorporate a layer of polypropylene foil, which shields the bituminous mass from environmental influences. This outer layer enhances the tape’s durability, ensuring its effectiveness even in extreme weather.

3. Release Liner

A release liner is affixed to the adhesive side of the tape, facilitating easy handling and application. This liner is removed when the tape is ready for use, guaranteeing a clean application and optimal adhesion.

4. Modified PE Material

Numerous contemporary hatch cover tapes, such as those provided by ChutuoMarine, employ modified polyethylene (PE) materials. The blue top layer of modified PE offers additional protection against moisture and ensures a robust seal.

Applications of Hatch Cover Tapes

1. Marine Cargo Transport

The foremost use of hatch cover tape is within the marine cargo transport industry. Ships frequently encounter severe conditions, such as rain, wind, and sea spray, which can jeopardize the safety of the cargo. By utilizing hatch cover tape, shipowners can guarantee that their cargo remains dry, safeguarding it against potential damage.

2. Shipbuilding and Repairs

In the processes of shipbuilding and repairs, hatch cover tape is employed to seal gaps and joints in hatch covers. This application is crucial for ensuring water-tightness and preventing unwanted leaks during testing and inspections.

3. Long-Term Storage

For vessels that may be docked for prolonged durations, hatch cover tape acts as an effective barrier against moisture and environmental harm. Shipowners frequently apply this tape during off-season storage to shield cargo holds from water ingress.

4. Compliance with Regulations

In accordance with international maritime regulations, hatch covers on cargo vessels must maintain water-tightness. The application of hatch cover tape assists shipowners in adhering to these regulations, reducing the risk of cargo loss and ensuring the safety of the vessel.

Why Choose Quality Hatch Cover Tape?

1. Proven Performance

High-quality hatch cover tapes, such as those provided by reputable suppliers like ChutuoMarine, have demonstrated a reliable performance history. Since their inception in the early 1970s, they have undergone testing under practical conditions and extreme standards, ensuring dependability across various applications.

2. Versatility

Hatch cover tapes come in a range of sizes and thicknesses, making them appropriate for different types of vessels and cargo holds. Whether you need a heavy-duty tape for severe conditions or a lighter alternative for standard use, there exists a hatch cover tape that meets your requirements.

3. Cost-Effectiveness

Investing in high-quality hatch cover tape can lead to substantial savings for shipowners over time. By preventing water damage to cargo, these tapes help mitigate expensive losses and claims, making them a prudent investment for any shipping operation.

Tips for Applying Hatch Cover Tape

1. Surface Preparation

Prior to applying hatch cover tape, it is essential to ensure that the surface is clean and dry. Eliminate any dirt, oil, or debris that could impede adhesion.

2. Temperature Considerations

Hatch cover tape performs best when applied within the specified temperature range. For optimal results, it is advisable to apply the tape when temperatures are between 5°C and 35°C.

3. Proper Application

Gently peel the release liner and apply the tape uniformly across the hatch cover. Ensure that there are no air bubbles or wrinkles, as these can jeopardize the seal.

4. Regular Inspections

Following application, it is important to regularly inspect the hatch cover tape for any signs of wear or damage. Replace the tape as necessary to maintain ongoing protection for your cargo.

Click to view the video: Hatch Cover Tape Dry Cargo Hatch Sealing Tape — Instructions

Conclusion

Hatch cover tape is a vital tool in the maritime industry, safeguarding the safety and integrity of cargo during transit. With its specialized materials and established applications, it provides shipowners with a dependable solution for protecting their investments. By collaborating with reputable suppliers such as ChutuoMarine and following best practices for application, ship operators can significantly improve their operational efficiency and ensure compliance with international regulations. Whether you are engaged in ship supply, shipbuilding, or cargo transport, recognizing the significance of hatch cover tapes is crucial for success in the maritime sector.

Post time: Jul-11-2025