Due to the very nature of incompatibility between the large number and variety of chemical products, a ship may carry for transport, it is highly likely that any semblance of even small amounts of cargo residue between consecutive cargos will produce undesirable effects.

The direct impact of this is on the properties of the chemical cargo, and the risk of contamination leading to rejection of cargo and potential of claims especially for the ship owner / manager.

It is thus imperative that Cargo tank cleaning and fitness to load inspections are given its due importanc

cargo owners require carriage of an intermediate cargo, such as diesel oil, for three voyages after carrying crude oil or dirty products before clean products such as petrol can be transported. The intermediate cargo gradually cleans the tanks, pumps and piping for the subsequent clean oil product.

A crucial task: Tank cleaning

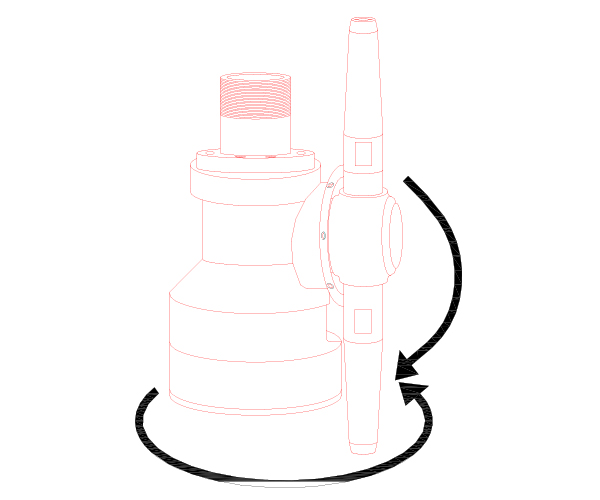

An alternative to intermediate cargoes would be to design a ship to enable switching between dirty and clean cargoes on a ballast voyage. This will however require thorough cleaning to remove traces of previous cargo from internal tank surfaces, cargo piping and cargo pumps and avoid contaminating the next product. Tank cleaning is performed by deck-mounted tank-washing machines.

The tanks are washed with seawater during a ballast trip and possibly rinsed with freshwater to remove the salt residue. There are certain designated areas where the washing water cannot be discharged. When the ship arrives at the next loading port, the tanks will be completely clean.

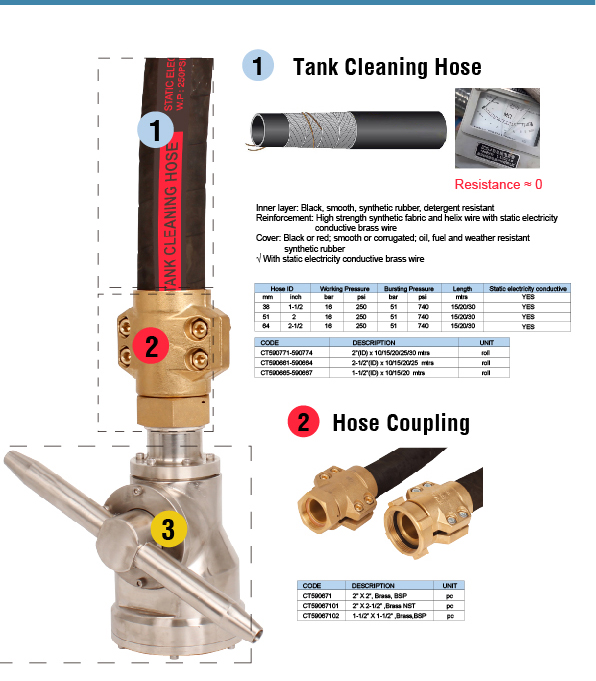

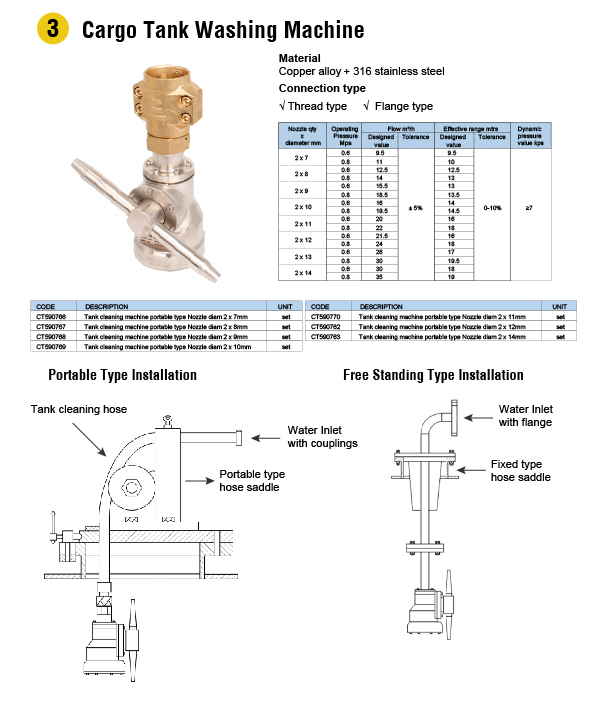

Our tank washing machines are known for their high-quality performance, efficiency, and durability. They are designed to effectively clean tanks of varying sizes, ensuring a thorough and hygienic cleaning process. With our extensive range, you can choose between portable and fixed twin nozzle tank washing machines, both offering exceptional results and user-friendly operation.

Key Features:

1. Versatility: Our tank washing machines can effectively clean various types of tanks, including those used in food processing, beverage production, chemical manufacturing, and wastewater treatment, among others.

2. Cleaning Efficiency: Our machines are engineered to provide high cleaning efficiency, removing stubborn residues and contaminants from tank surfaces, ensuring optimal hygiene and maintaining product integrity.

3. Durability: Crafted from robust materials, our tank washing machines are built to last, even in demanding industrial environments. They are resistant to corrosion and wear, guaranteeing longevity and reliability.

4. Easy Maintenance: Our tank washing machines are designed for easy maintenance and cleaning. With minimal efforts, you can keep them in optimal working condition, reducing downtime and maximizing productivity.

5. Safety: We prioritize safety in our product design. Our tank washing machines incorporate safety features such as pressure regulation systems and nozzle guards, ensuring operator safety and preventing damage to tanks.

Overview of Cargo Tank Washing Machine

Model YQJ-Q and B tank washing machines are manufactured with advanced technology and high-quality materials. Compared with the traditional similar cleaning machine, it is quite different. The cleaning machine not only has low pressure when cleaning, it also has a long range and the structure of the whole machine is combined. The whole machine is composed of three parts: pressure water cavity, speed change mechanism and automatic clutch nozzle. The three parts can be installed, disassembled, repaired and replaced independently, with simple structure and convenient maintenance. The transmission of the tank washing machine adopts new copper graphite and stainless steel bearing, which has small wear and durability

The traditional tank washing machine is easy to be damaged.When service is needed and turbine, turbine rod and shaft sleeve need to be repaired, all parts must be removed. However, the crude oil tank washing machine only needs to remove a few screws to replace the whole transmission mechanism.

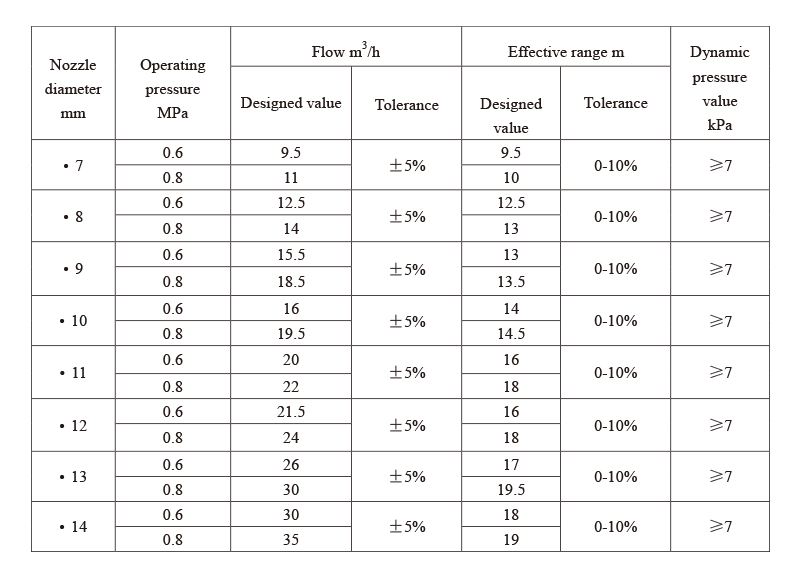

Technical Parameter

1.Tank washing machine can be operated normally when vessel heeling 15°, rolling 22.5°, trim 5° and pitching 7.5°.

2.Operation temperature is from normal temperature to 80℃.

3.The diameter of pipes for the tank washing machines should be wide enough for all required tank washing machines to work simultaneously under the designed parameters.

4.Tank washing pump can be cargo oil pump or specialized pump the flow of which can make several tank washing machines can work under designed operation pressure and flow.

Supply Parameter

Tank washing machine type YQJ B/Q is operated with the cleaning medium with flow of about 10 to 40m3/h and with the operation pressure of 0.6-1.2MPa.

Weight

The weight of tank washing machine type YQJ is about 7 to 9kg.

Material

Material for tank washing machine type YQJ is copper alloy, stainless steel including 316L.

Performance data

Following table shows the inlet pressure, nozzle diameter, probable flow and jet length for each tank washing machine.

Post time: Sep-07-2023